Our speciality fans are intended for customers with special requirements due to untypical application (transported medium) or fan construction design. We offer fans in special versions to meet such requirements. Standard fans are redesigned according to the specific needs of the target user. These fans are used in a variety of industrial sectors and meet even the most demanding requirements. They also make it possible to shorten production processes in the case of machines with built-in fans

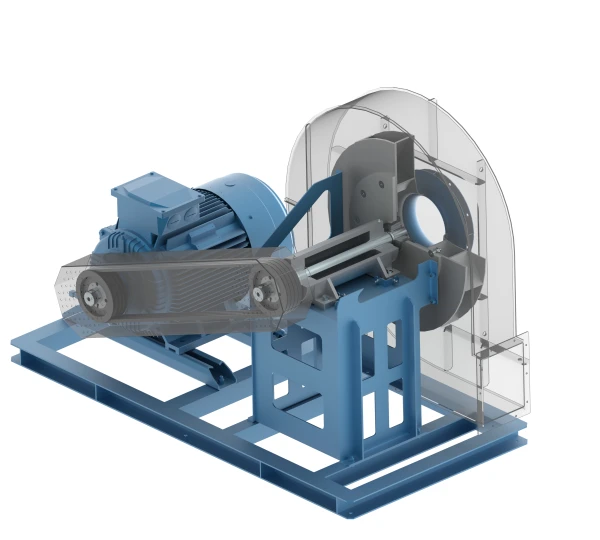

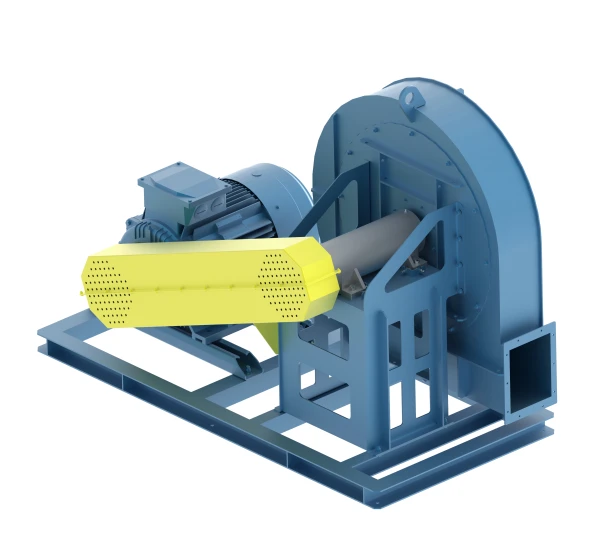

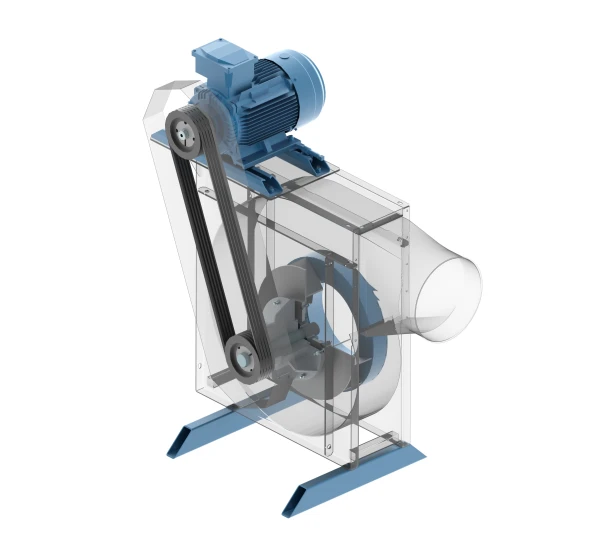

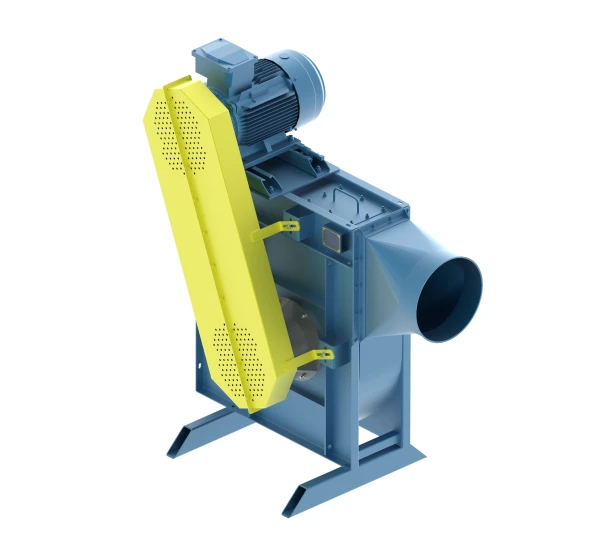

First of all, thanks to the belt drive, it is possible to relocate the motor away from the fan axis, so the unit can be installed in confined spaces. In addition, the belt drive allows adjustment of the operating parameters without the need for an inverter, increasing flexibility of use and adaptation to different operating conditions.

These fans can replace standard direct drive fans, whenever there may be a risk of significant, undesirable loading on the motor bearings in certain applications, for example during transport. This solution protects the motor bearings, thereby increasing their durability and reliability.

Advantages:

- Despite the use of a belt drive, the fans maintain a high level of efficiency, allowing for high efficiency and energy-saving operation.

- No inverter is needed to adjust the parameters, which simplifies the control process.

- The fans have a robust explosion-proof design

- Single inlet.

Every standard fan can be manufactured in the K-type version with a belt drive.

The belt-drive fan offers a number of advantages that make it an exceptional choice for various industrial applications. First of all, thanks to the belt drive, it is possible to move the motor away the fan axis, which allows the unit to be installed in confined spaces. In addition, the belt drive allows the parameters to be adjusted without the need for an inverter, which increases flexibility of use and adaptability to different operating conditions.

c.fischer@netecs.eu