Kategorie produktów

Wybierz interesującą Cię kategorię naszych produktów

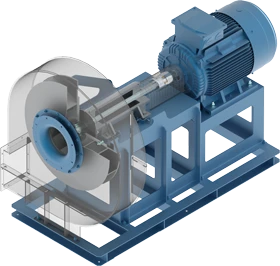

Wentylatory promieniowe

Wentylatory przeznaczone do przetłaczania powietrza, mieszaniny pyłu wraz z powietrzem, rozdrabniania i transportu frakcji stałej oraz przystosowane do wysokich temperatur.

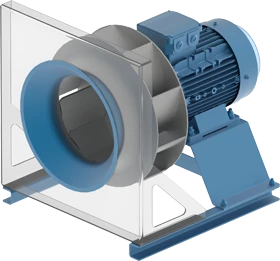

Wentylatory promieniowe bez obudowy

Wentylatory bez obudowy przeznaczone do przetłaczania czystego, poddanego filtracji bądź lekko zapylonego powietrza.

Akcesoria do wentylatorów

Elementy usprawniające prace wentylatorów, zmniejszające hałas i tym podobne rzeczy

Potrzebujesz doradcy?

Aby uzyskać lokalne wsparcie techniczne i pomoc skontaktuj się z nami.

Odpowiemy na każde Państwa pytanie dotyczące produkcji, montażu i serwisu urządzeń.

skontaktuj się

Clemens Fischer

Inżynier sprzedaży na rynek niemiecki

c.fischer@netecs.eu

Wentylatory promieniowe dla twojej branży

ZOBACZ WSZYSTKIENasze wentylatory znajdują najczęściej zastosowanie w instalacjach odpylania w branży drzewnej, w tym stref zagrożonych wybuchem oraz w zakładach zajmujących się przetwarzaniem odpadów. Ze względu na ciągły rozwój produkty i rozwiązania firmy coraz częściej są obecne w przemyśle energetycznym i ciepłownictwie, gdzie zastosowanie znajdują wysokotemperaturowe wentylatory do odciągu spalin, o wysokiej efektywności energetycznej.