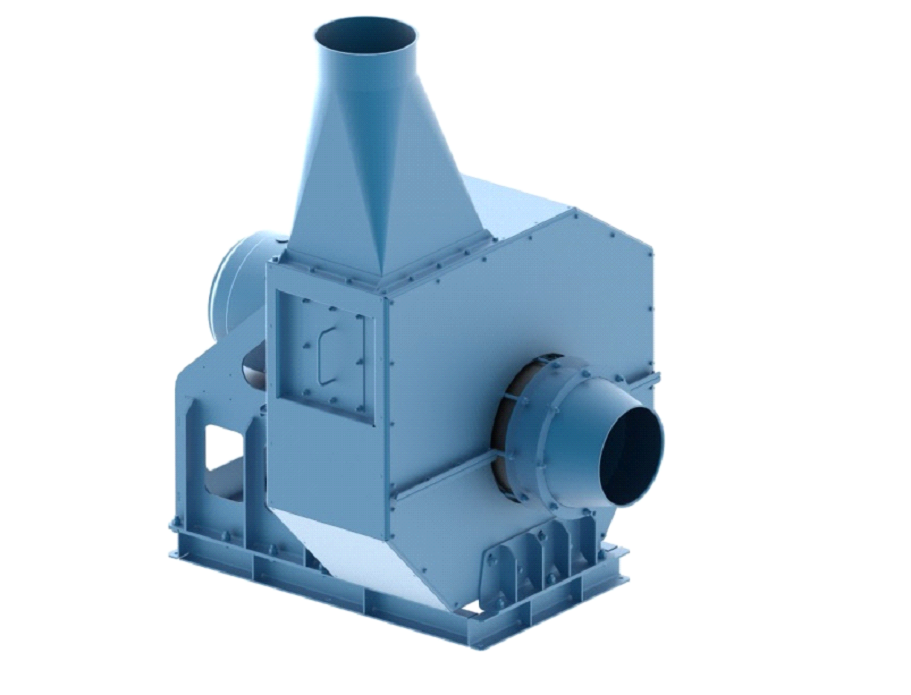

Shredding fans

The main function of shredding fans is to shred pneumatically transported material of considerable or even endless length.

The shredding fans are designed for many years of trouble-free operation. A grade of steel with increased flexural strength and high material thickness was chosen for fabricating the rotors, preventing deformation of the rotor blades and therefore increased wear of the motor bearings. The special cutting and shredding knives and teeth are adapted to the respective transported material.

The design of the shredding fans prevents the shredded transported material from adhering to the rotor, which could interfere with fan operation. Even though the fans are designed for cutting and shredding, they are constructed for many years of trouble-free operation thanks to the use of highly wear-resistant shredding knives and teeth. The efficiency of these fans can be as high as 38% depending on the version and transported material. A special, adjustable fan intake allows the gap between the rotor and injection port to be adjusted, ensuring an optimal airflow with the material being shredded.

Advantages:

• Modular design

• Sturdy, leak-proof welded construction

• Special cutting knife system made of high-strength steel

• Ability to adapt gap between the rotor and injection port thanks to a special, adjustable fan intake

• Suitable for outdoor and indoor use

• Sound insulation available

Others from the series: