Radial fans - an efficient solution for industry

Radial fans are a key component of modern industrial ventilation systems. Thanks to their ability to generate high pressure and operate in demanding conditions, they are used, among others, in . energy, metallurgy, wood industry or waste management. Their robust construction, high performance and adaptability to the specifics of the plant make them indispensable where reliability and efficient movement of air or other substances are important. Netecs offers a wide range of models to suit a variety of technological needs.

Radial fan - applications, types and key features?

Industrial fans, also known as radial fans, are an essential component of industrial ventilation systems. Netecs Sp. z o.o., which has been in operation since 2005, specialises in the production of this type of equipment and has over 4,000 models in its range. Thanks to their robust construction and powerful motors, Netecs fans ensure efficient airflow and material transport even in the harshest industrial environments. The greatest advantage of these units is their ability to generate high pressure, making them indispensable where intense air circulation and solid fraction transport.

Despite the dynamic development of technology, radial fans remain irreplaceable. Their reliability and efficiency make them one of the most frequently chosen solutions in modern ventilation and production systems.

What are radial fans?

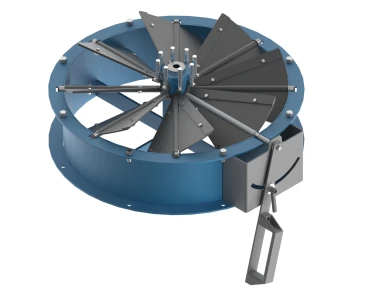

A radial fan is a ventilation device that, thanks to its multi-bladed impeller, generates high pressure and enables air and particles to be pumped through in a variety of industrial applications.

Thanks to its robust construction and powerful electric motor, it can operate under heavy load, making it extremely versatile.

Structure and working principle

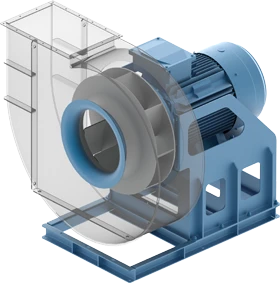

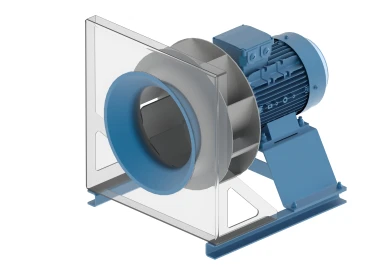

The radial fan consists of several essential components, the most important of which is the multi-bladed steel impeller. It is responsible for moving air and generating high pressure in an efficient way.

The fan also consists of:

- a suction box

- inlet funnel

- motor undertray

- suction plate

- motor

- housing

- support

Thanks to such design, radial fans are ideal for applications where a constant and intensive air and particle flow is required.

These are elements of our standard fans, but we offer many different models which, depending on the application and required parameters, may differ in design and execution, e.g. by adding soundproofing or a silencer.

Types of radial fans

Radial fans, also known as industrial fans, come in many versions to suit different applications. Among the most commonly selected models are the FHN, SFN and VS. Each has unique features that make them ideal for the conditions and situations for which they are adapted.

We offer the following categories of fans:

Fans designed for handling clean or filtered air

Available types: PREMIUM FHN, PREMIUM SFN, CLASSIC SFN

Fans designed for handling low density air/dust mixtures.

Available types: PREMIUM VS, CLASSIC VS

Fans designed for handling air-solid mixtures.

Available types: PREMIUM EN, CLASSIC EN, PREMIUM RN, PREMIUM S VM/SF, PREMIUM S, CLASSIC S

Fans designed for shredding or cutting pneumatically conveyed material of considerable lengths.

One type is available: PREMIUM TN

Fans designed for forcing a mixture of hot air and low-density dust.

One type is available: PREMIUM HT

📌 Recirculation fans - vertical

Fans intended for transport of clean or slightly dusty air

Available types: PREMIUM WR-SFN, PREMIUM WR-SV

Fans designed for transport of clean or slightly dusty air

Available types: PREMIUM WH-VS, PREMIUM WH-SFN

Special solutions for customers with specific requirements

Available types: PREMIUM K, PREMIUM C, PREMIUM D

➡️ Our complete range including accessories can be found here

What technological innovations can further improve the efficiency of radial fans? Will the development of intelligent control systems allow for even better optimisation of their operation? The future will bring answers, but one thing is certain - ventilation technology is constantly evolving!

Radial fan applications

Radial fans, are the cornerstone of modern ventilation systems. Their ability to generate high pressure makes them indispensable in many sectors - from industry to agriculture. Where exactly do they play a key role? Let's take a closer look:

- Woodworking industry

- Energy and heating industry

- Waste management

- Agri-food industry

- Plastics processing

- Metallurgy

➡️ Find out more details about the sectors that use our fans

How to choose the right radial fan?

The selection of a radial fan is a key element of effective ventilation. In order to make the best decision, it is worth analysing several important aspects: capacity, power and operating conditions. Each of these factors affects the performance of the device in a given environment. To streamline this process, Netecs offers an innovative NVS (Netecs Ventilator Selection) tool, enabling:

- Selection of the right fan depending on the conveyed medium

The most important parameters for consideration include:

- Capacity - the amount of air the fan can convey per hour, expressed in cubic metres per hour (m³/h).

- Power - determines the ability of the unit to generate adequate pressure and airflow.

- Specific application - will the fan be operating at high temperatures, in high humidity or in the vicinity of chemicals? The right choice of model will ensure reliability and a long service life.

Selecting the right model is the key to efficient operation of the ventilation and production system. An analysis of the operating conditions will allow you to select the device that best meets your expectations.

Have you ever wondered how a properly selected fan can boost the efficiency of your plant?

Impeller diameter and design

Impeller diameter and design have a huge impact on the performance of a radial fan. The impeller, which is the heart of the unit, is responsible for efficient transport of the air or solid fraction and has an impact on the fan performance.

- Impeller diameter - the larger the impeller, the more air can be processed. The choice of the appropriate diameter should take into account the specifics of the ventilation system.

- Impeller design - made of durable materials, ensures resistance to heavy-duty operation and harsh working conditions.

Resistance to difficult operating conditions

One of the greatest assets of radial fans is their resistance to difficult conditions. Thanks to their robust construction and high-quality materials, they can operate in extreme environments where other devices would fail.

Radial fans perform well in areas with:

- high humidity - they provide effective ventilation even in demanding conditions.

- elevated temperatures - the resistance to heat allows for long and trouble-free operation.

- chemicals presence - special construction materials protect against corrosion and degradation.

- elevated risk of ATEX explosion hazard - meeting the highest standards in accordance with current Ex standards.

When choosing a radial fan, it is worth paying attention to its resistance to harsh conditions in order to ensure long-lasting and efficient operation of the ventilation system.